Welcome At Shaft Lead

Introduction Of Innovation

RiM LaS Private Limited owns Shaft Lead. Matesy GmbH has chosen us as a particular Nation Sales Partner for India for the entire range of Shaft Twist Testers (Shaft Lead Tester). Matesy GmbH, based in Germany, is a technology innovator and manufacturer of Shaft Lead Tester and other magnetic testing instruments.

In terms of technological developments and products, RiM LaS is a trailblazer. Over the years, we’ve put in a lot of effort to make valued and unique ideas a reality. To achieve so, we collaborated with a variety of high-quality product development companies around the world. With our cutting-edge technology, we’ve forged strong ties with a number of Indian companies, acquiring a strong foothold and making a substantial contribution to the country’s industrial development. We are always looking for new and unique ideas to help us influence the future of Indian industry.

Introduction Of Our Principle

Technological Innovation

Matesy GmbH is a cutting-edge technology firm based in Jena’s university district. Matesy specialized in the fabrication of Instruments for visualization, characterization, generation of magnetic fields, and shaft twist testing when it was founded in 2008 as a spin-off from the R&D institute “INNOVENT Technologieentwicklung.”We develop and create systems and technologies at the highest level in order to achieve our claim of qualitative market leadership in this category.

For this, we collaborate closely with external research and industry partners. Our collaborations vary from the active exchange of know-how to the active transfer of business through the shared use of resources. Matesy represents the production and sales platform for the unique goods generated by numerous research organizations, including INNOVENT technological development, Jena University of Applied Sciences, and Fraunhofer institutes. Matesy features a simple framework and a quick decision-making process.

STT - Shaft Twist Tester

Twist test without thread & profilometer

In order to avoid a leak in a radial shaft seal, the sealing surface of the shaft must be made twist-free. Through the optical diffraction, twist structures can be made visible, the amplitudes of which are well below the roughness amplitudes of the sealing surface. Quality control in the immediate vicinity of the machining process can thus be carried out quickly and reliably. With test times in the range of seconds, the shaft lead tester can be used in a variety of ways, e.g. for incoming inspection, for process optimization of the manufacturing process or for 100% (quality) control in series production.

Application background

Measurement methods & advantages

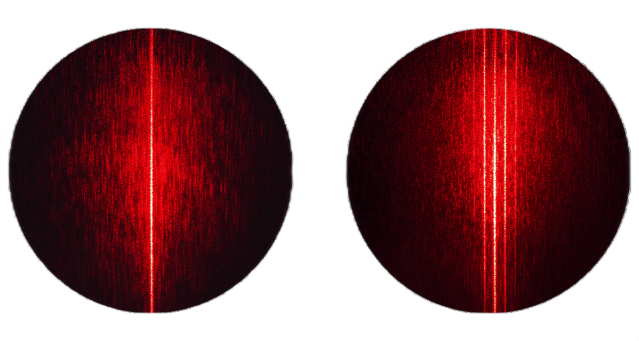

The twist of a shaft seal determines its sealing function in a major parts. The rotation of the shaft begins a significant micro-pumping effect as soon as there is a twist, causing the liquid to escape or wear on the component. The Shaft Twist Tester can exactly visualize these twist configurations. Optical filtering reveals the existence of twist on the test object surface and allows for the estimation of twist parameters such as twist depth and period duration. The twisted depth is measured by the number and brightness of diffraction lines exhibited, and the period length is measured by their distance.

Measurement method

Twist structure mapping was previously only achievable with extremely difficult and expensive tactile form measurement technologies. Due to the long measurement duration and tight measuring conditions, a production-related test could not be performed. Alternatively, the thread approach can be employed, however, it is subject to a variety of boundary constraints (e.g. thread material, thread thickness, attached weight, or viscosity of the lubricant). The approach clearly fails with extremely small or very large twist structures, which is the method’s fundamental shortcoming.

Advantages of the STT-shaft twist tester

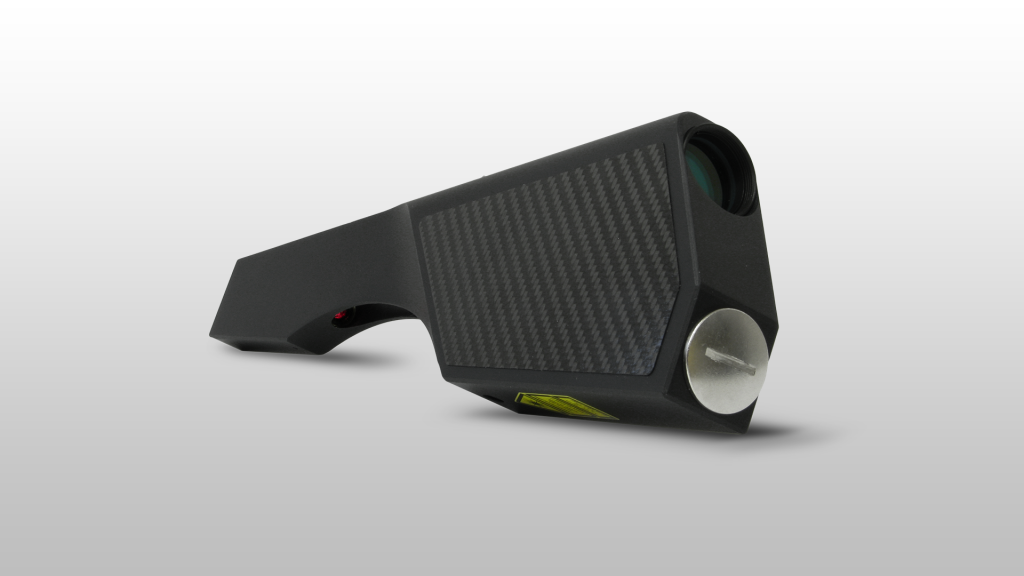

Twist is currently measured using either the thread method or a profilometric measurement equipment as standard. Both technologies are insufficient for speedy application in the manufacturing process or complete control. With the STT, test equipment that fits these requirements and combines reliable twist testing with high user-friendliness has been developed. On the test object, the shaft twist tester hand-held device is put. Using a system of strips in the field of vision, the inspector can detect the existence of twisted structures on the surface of the manufactured component right away.

Shaft Twist Tester Variants

There are 3 variants - NO, NK, NV

STT - Shaft Twist Tester NO

- Twist test as close to production as possible

- Lasers are a type of technology

- A magnifying glass is built-in

- High level of repeatability

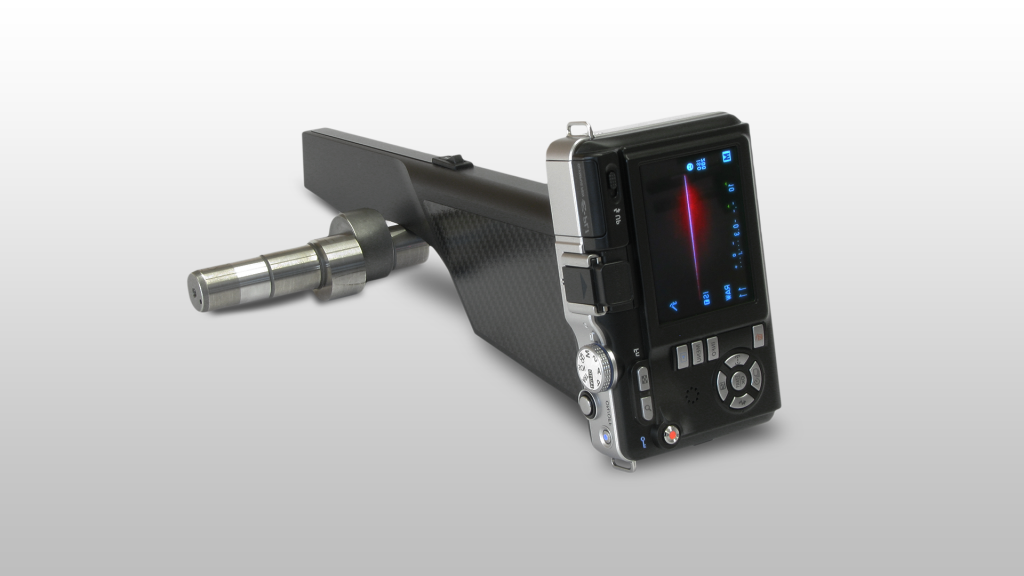

STT - Shaft Twist Tester NK

- Adapted digital camera

- Twist test close to production

- Evaluation and archiving software

- Laser technology

STT - Shaft Twist Tester NV

- Integrated video camera

- Setup as a twist test bench Twist test on the monitor

- Ideally suited for 100% control

- Twist test on the monitor